Cutting-edge Innovation in Rubber Reactor Technology Unveiled in Latest News

By:Admin

Introduction:

In an exciting breakthrough for the rubber manufacturing industry, a pioneering company has unveiled a cutting-edge rubber reactor capable of transforming the production process. This game-changing technology is set to redefine the way rubber is manufactured and holds the potential to revolutionize the industry on a global scale.

[Company Name], a renowned leader in innovative solutions for industrial manufacturing, has developed and successfully deployed a state-of-the-art rubber reactor that promises to streamline production, increase efficiency, and significantly reduce environmental impact.

Paragraph 1:

Constructed with precision engineering, the new rubber reactor marks a significant leap forward in the manufacturing of rubber compounds. By integrating advanced automation and enhanced chemical processes, the reactor enables companies to optimize their production line, ensuring the consistent delivery of high-quality rubber products.

Paragraph 2:

One of the most remarkable features of this breakthrough technology is its ability to reduce waste during the manufacturing process. Through a combination of advanced software algorithms and real-time monitoring, the reactor minimizes material wastage, resulting in cost savings and increased sustainability. This development aligns perfectly with the growing global demand for environmentally conscious manufacturing practices.

Paragraph 3:

In addition to its waste reduction capabilities, the reactor also boasts an impressive increase in production efficiency. By leveraging cutting-edge robotics and artificial intelligence, the technology allows for quicker and more precise mixing, blending, and curing of rubber compounds. This speed and accuracy lead to higher output levels while maintaining consistent quality at every stage of the process.

Paragraph 4:

With this innovative solution, manufacturers can now enjoy greater control over the production of rubber compounds. The reactor's intelligent systems allow for customization and adjustment of product specifications, ensuring optimal performance for a wide range of industrial applications. From the automotive and aerospace sectors to industrial machinery and consumer goods, the reactor's versatility holds immense potential for diverse industries.

Paragraph 5:

The impact of this breakthrough technology is not limited to manufacturing alone. By reducing waste and increasing efficiency, the rubber reactor also contributes to the overall sustainability goals of companies and helps meet stringent environmental regulations. As organizations aim to minimize their carbon footprint and adopt greener practices, this revolutionary technology presents an opportunity for them to align their production processes with their environmental commitments.

Paragraph 6:

[Company Name] firmly believes that the rubber reactor will catalyze a paradigm shift in the rubber manufacturing industry. By optimizing efficiency and reducing waste, the technology sets a new benchmark for sustainable practices. With its potential to transform production processes on a global scale, the reactor has the power to reshape the industry's landscape and drive advancements that benefit both businesses and the planet.

Conclusion:

The introduction of the cutting-edge rubber reactor by [Company Name] presents an exciting turning point for the rubber manufacturing industry. With its remarkable waste reduction capabilities, increased production efficiency, and compatibility with diverse industrial applications, this breakthrough technology brings significant benefits to manufacturers worldwide. As the demand for sustainable practices grows, the rubber reactor emerges as a game-changing solution that not only improves manufacturing processes but also contributes to a greener, more environmentally conscious future.

Company News & Blog

Learn How to Easily Make Homemade Apple Cider Vinegar at Home

Apple cider vinegar is a popular ingredient in many household kitchens, as it can be used for a variety of purposes. It is known for its numerous health benefits, such as reducing blood sugar levels, aiding in weight loss, and improving digestion. While it is easily available in stores, making apple cider vinegar at home is a cost-effective and simple process. All that is needed is a few basic supplies and a bit of patience.Equipment needed for vinegar productionBefore we dive into the process of making apple cider vinegar, it is important to gather the necessary equipment. The following items are required for the production of apple cider vinegar: - Glass jar or crock - Cloth or paper towel - Rubber band - Apple scraps or cider - Sugar - Water - Glass bottles with stoppers The container used for apple cider vinegar production should be made of glass, as plastic and metal can react with the vinegar and affect its taste. A large glass jar or crock is preferable to allow for enough space for the apple scraps or cider as well as air circulation. A cloth or paper towel should be used to cover the jar or crock and allow air passage while preventing dust or debris from entering. A rubber band can secure the cloth or paper towel over the jar.The second set of equipment required to make apple cider vinegar is the ingredients. Apple scraps or cider, sugar, and water are necessary to create an environment that promotes the growth of acetic acid bacteria and fermentation.How to make apple cider vinegarMaking apple cider vinegar is a simple process that requires only a few steps:1. Prepare the apple scraps or cider - Apple scraps can be collected from any variety of apple by slicing off the core and any blemishes or bruises. The scraps should be rinsed, placed in the jar, and covered with water. If apple cider is being used instead of scraps, it should be poured into the jar.2. Add sugar - Sugar is added to the jar to help promote the growth of acetic acid bacteria. For every cup of apple scraps or cider, one tablespoon of sugar should be added. The sugar should be stirred until dissolved.3. Cover the jar - The jar should be covered with a cloth or paper towel and secured with a rubber band. The jar should be kept in a cool, dark place for two weeks. The jar should be stirred every few days to promote air circulation and encourage the growth of acetic acid bacteria.4. Strain and Bottle - After two weeks, the apple cider vinegar should be strained through cheesecloth or a fine mesh strainer. The liquid should be poured into glass bottles with stoppers and stored in a cool, dark place for four to six weeks, allowing the vinegar to mature and fully develop its flavor.ConclusionMaking apple cider vinegar at home is a fun and cost-effective process. With the right equipment and ingredients, it is easy to create a delicious and healthy vinegar that can be used in a variety of ways. From salad dressings to cleaning solutions, apple cider vinegar has several uses in the household. With a bit of patience and effort, anyone can produce a high-quality apple cider vinegar in the comfort of their own home.

Next-Generation Induction Tank Boosts Efficiency and Saves Energy

In recent years, the demand for induction furnaces and tanks has steadily increased, particularly in industries such as metallurgy, energy & power, and mining. These industries have recognized induction furnaces' features like faster heating times, lower energy consumption, and less environmental impact. Companies such as Induction Tank, one of the leading manufacturers of induction furnaces, have been operating for years successfully. They are committed to providing high-quality and reliable induction furnaces and tanks.Induction Tank is a private company working in the field of high-frequency induction heating. It is headquartered in California and operates in different states and countries. The company produces a wide range of induction heating equipment, including induction technology, induction heaters, power supply units, water-cooled cables, and components, and tailored equipment solutions. Induction Tank's products are suitable for operating at temperatures from 100°C to 2500°C and with heating capacities ranging from a few kilowatts to several megawatts. They are used mainly for heating metals and alloys for industrial processes like melting, casting, forging, and heat treatment.One of Induction Tank's new products is the induction tank. An induction tank is a tank with a metal lining, along with induction heating technology, used primarily for heating and melting metal. Induction tanks offer several advantages over traditional heating tanks. First, by using electromagnetic induction, they are energy-efficient and require less time and less energy to heat and operate. Second, induction tanks have a smaller footprint, making them ideal for installation in tight spaces. Third, induction tanks produce less waste, making them more eco-friendly compared to traditional heating methods.Induction tanks are now widely used in various industries for a variety of purposes, such as melting metals, maintaining heating equipment, and maintaining temperature consistency in industrial processes. For instance, they are used in the glass and ceramic industry, where they are ideal for melting glass and ceramics. Additionally, induction tanks are used in the steel industry for alloying and melting iron and steel scrap and for heating and melting precious metals like gold and silver in the jewelry-making industry.Induction Tank's induction tanks come in different designs and sizes, each tailored to meet specific customer needs. They are available in standard sizes, or customers can order customized tanks that meet their exact requirements. The company's staff works closely with its customers to ensure they specifically understand the clients' needs and develop products that exceed their expectations.Induction Tank's induction tanks feature high performance, efficiency, and durability. They are designed to last for many years while requiring minimal maintenance. The company has an excellent warranty and customer service policy, ensuring that clients always receive the support they need.In conclusion, Induction Tank is an innovative and forward-thinking company that has managed to carve a niche for itself in the induction heating industry. The company's induction tanks are among their premium quality products. They are durable, efficient, and eco-friendly and are ideal for various industrial applications. With the company's commitment to customer satisfaction, it is no surprise that Induction Tank has become a reputable brand in the industry.

GUM Releases "Low to Low" Music Video, New Album Out Now

Title: Exploring the Magical World of Chewing Gum: A Journey into the Making and MachineryIntroduction (100 words):Welcome to our blog, where we embark on a fascinating journey into the world of chewing gum production and the intricate machinery behind it. In this article, we'll delve into the process of making chewing gum and the important role played by specialized machines. So, sit back, relax, and join us as we explore the magical world of gum production.1. The Art of Gum Manufacturing (200 words):The production of chewing gum has come a long way since its humble beginnings. Today, it has become a multi-billion-dollar industry, with a wide range of flavors, textures, and packaging options to entice consumers.The art of gum manufacturing involves several key steps, including ingredient preparation, mixing, extrusion, cooling, cutting, and packaging. Each stage requires meticulous attention to detail to ensure the final product meets the desired quality standards.2. The Role of Machines in Gum Production (200 words):As the demand for chewing gum continues to rise, manufacturers have turned to advanced machinery to streamline the production process. These machines play a critical role in ensuring efficiency, uniformity, and consistency in gum production.One such machine is the "Machine To Make Gum," which is commonly used in the industry. This specialized equipment is designed to handle the various stages of gum manufacturing seamlessly.The Machine To Make Gum incorporates cutting-edge technology to precisely mix the gum base with flavorings, sweeteners, and additives. Its advanced extrusion system allows for consistent shaping and sizing of the gum, while maintaining the desired texture. Additionally, this machine efficiently cools the extruded gum, preventing any loss of flavor or quality during the process.3. Benefits of Using the Machine To Make Gum (200 words):The adoption of specialized machinery, like the Machine To Make Gum, offers numerous benefits to chewing gum manufacturers. Let's explore some of the advantages it brings to the production process:a. Enhanced Efficiency: The machine automates several manual tasks, significantly increasing production capacity and reducing labor requirements. As a result, manufacturers can meet high demands while keeping costs in check.b. Consistent Quality: The precise control and monitoring capabilities of the machine ensure that every piece of gum produced adheres to the desired standards of texture, flavor, and size. This consistency is vital to building brand loyalty and satisfying consumer expectations.c. Versatility: The Machine To Make Gum can adapt to different gum recipes, allowing manufacturers to experiment with new flavors and formulations. This versatility enables the creation of unique products to cater to diverse consumer preferences.4. The Future of Gum Production Machinery (150 words):As technology continues to advance, the future of gum production machinery holds exciting possibilities. Innovations such as automated packaging systems, robotic handling, and improved gum inspection and sorting technologies are on the horizon.Augmented reality might also play a role, allowing manufacturers to visualize and optimize the production process, further enhancing efficiency and reducing waste.Conclusion (150 words):Chewing gum production has become an art form, with specialized machines like the Machine To Make Gum leading the way. These machines offer unmatched efficiency, consistency, and versatility, revolutionizing the manufacturing process.As manufacturers strive to meet growing consumer demands, investing in advanced gum production machinery becomes imperative. The future promises even more exciting developments, ensuring that the gum industry continues to offer innovative, high-quality products that capture the taste buds of consumers worldwide.So, the next time you enjoy a piece of chewing gum, take a moment to appreciate the craftsmanship and machinery that bring this seemingly simple pleasure to life.

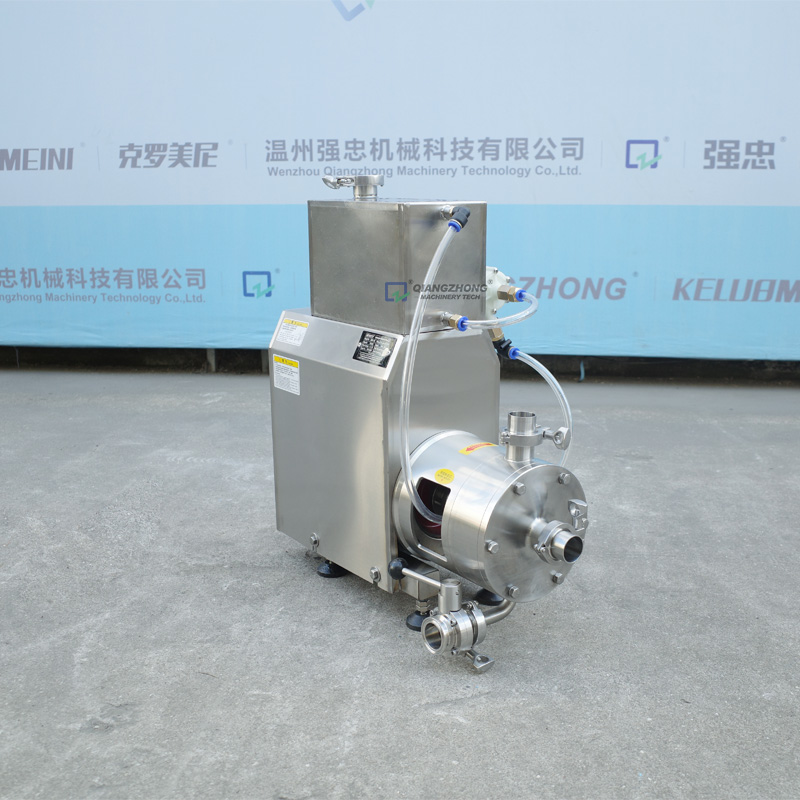

New Pump Machine for Making Delicious Ice Cream at Home

Ice Cream Pump Machine Revolutionizes Soft Serve ProductionIn the world of ice cream production, speed, efficiency, and quality are key. And for many businesses, the key to success lies in investing in the right equipment. That's where the innovative new Ice Cream Pump Machine comes in.Developed by a leading manufacturer of ice cream equipment, this cutting-edge device is designed to revolutionize the way soft serve ice cream is produced. Featuring a range of advanced features and capabilities, it promises to deliver faster, smoother, and more consistent production, helping businesses to meet the growing demand for high-quality soft serve products.So what sets the Ice Cream Pump Machine apart from other soft serve machines on the market? First and foremost is its unique pumping system, which uses a gentle, low-shear process to ensure a smooth and consistent product every time. Unlike traditional soft serve equipment, which uses high-pressure air to force mix through a nozzle, the Ice Cream Pump Machine pumps the mix through a series of gentle chambers before dispensing it in a silky stream.According to the company, this innovative pumping system has several key benefits. First, it eliminates the need for air compressors, reducing energy costs and noise levels. It also reduces the strain on the mix, resulting in a product that is smoother, creamier, and more consistent. And because the mix is pumped at a slower speed, it has more time to absorb air and flavorings, resulting in a richer and more complex product.But the Ice Cream Pump Machine isn't just about the pumping system. It also boasts a range of other features that make it a standout choice for businesses looking to maximize their ice cream production. These include:- An intuitive touchscreen interface that allows operators to easily control and adjust the machine's settings, including flavor and consistency.- A self-cleaning cycle that eliminates the need for manual cleaning and reduces downtime between batches.- A high-capacity hopper that can hold up to 26 liters of mix, reducing the need for frequent refilling.- A compact footprint that makes it ideal for businesses with limited space.Together, these features make the Ice Cream Pump Machine a versatile, efficient, and reliable solution for businesses of all sizes. Whether you're a small ice cream stand or a large chain, this innovative machine promises to deliver fast, efficient, and high-quality soft serve production.Of course, the Ice Cream Pump Machine is just one of many innovative products offered by this leading ice cream equipment manufacturer. With a long history of cutting-edge design and engineering, the company has earned a reputation as a trusted partner for businesses around the world.From soft serve machines to batch freezers, pasteurizers, and more, the company offers a comprehensive range of equipment to meet the needs of any ice cream production operation. And with a commitment to quality, reliability, and customer service, it's no wonder that so many businesses turn to this leading manufacturer again and again.So if you're looking to revolutionize your soft serve production, consider the Ice Cream Pump Machine and its many impressive features. With its advanced pumping system, intuitive controls, and high-capacity hopper, it promises to deliver faster, smoother, and more consistent production than ever before. To learn more about this innovative machine and other cutting-edge ice cream equipment from this leading manufacturer, visit their website today.

Grind Your Own Matcha Tea at Home with These Top Tools

In recent years, the popularity of Matcha tea has skyrocketed, and with this new trend, an innovative new tool has emerged, the Matcha Tea Grinder. This new device has been designed to grind the Matcha tea leaves to a very fine powder, allowing the tea to be easily whisked into a delicious and frothy beverage.The Matcha Tea Grinder is a product of extensive research and development by a team of experts in Japan, who have been dedicated to crafting and perfecting the art of Matcha tea for generations. Their passion for this unique beverage has led them to develop a product that not only enhances the flavors of Matcha tea but also makes the preparation process fast and effortless.The Matcha Tea Grinder is a sleek and compact device that can be easily stored away when not in use. The grinder is made to be durable and long-lasting, ensuring that it can be used time and time again without any wear or damage. The device has been designed to grind Matcha tea leaves to a precise consistency, ensuring that the tea powder produced is of the highest quality.Using the Matcha Tea Grinder is simple and easy. Users simply need to add the desired amount of tea leaves to the grinder and turn the device on. The grinder is equipped with a powerful motor that ensures the leaves are ground efficiently and quickly. The ground Matcha tea powder is then ready to be whisked into a smooth and creamy drink.The Matcha Tea Grinder is perfect for home and commercial use. Home users can now enjoy a perfectly prepared Matcha tea in the comfort of their own home, without needing to visit specialty cafes or tea shops. Commercial users, such as cafes and restaurants, can effortlessly prepare high-quality Matcha tea for their customers, ensuring a delicious and consistent product every time.Not only is the Matcha Tea Grinder convenient and easy to use, but it also provides a host of health benefits. Matcha tea is known for its high levels of antioxidants, which can help boost the immune system and improve overall health. By grinding the tea leaves to a fine powder, the nutrients and antioxidants in the tea are more easily absorbed by the body, providing even greater health benefits.In conclusion, the Matcha Tea Grinder is an innovative and revolutionary device that has changed the way people prepare and enjoy Matcha tea. With its sleek design, durable construction, and ease of use, the Matcha Tea Grinder is perfect for both home and commercial use. By grinding the leaves to a fine powder, the device enhances the flavor and aroma of the tea, while also providing a host of health benefits. It’s no wonder that the Matcha Tea Grinder has quickly become an essential tool for tea lovers across the globe.

Stylish and Functional Lotion Pump: Discover the Latest Brass Design

Title: Innovative Brass Lotion Pump Unveiled: Elevating Skincare Experience to New HeightsIntroduction:In a bid to revolutionize the skincare industry, a leading manufacturer has unveiled its latest creation: the groundbreaking Brass Lotion Pump. Combining functionality, aesthetics, and sustainability, this innovative pump seeks to enhance the skincare experience for users worldwide. Created by [Company Name], a renowned industry player, the Brass Lotion Pump is poised to set a new benchmark in terms of performance, design, and environmental consciousness.(Insert relevant information about the company)Functionality:The Brass Lotion Pump boasts an array of cutting-edge features, offering an unparalleled experience to skincare enthusiasts. With an ergonomic design, it ensures easy and controlled dispensing of lotions, serums, and creams. Its smooth operation ensures an optimal dosage each time, eliminating potential wastage and mess. By incorporating advanced technology, the pump delivers a consistent flow, allowing users to apply their preferred products effortlessly.Additionally, the Brass Lotion Pump introduces a unique anti-drip mechanism, preventing messy accidents and maximizing product usage. Built to withstand the demands of daily use, its durable construction guarantees long-lasting performance. Whether used at home or in professional settings such as beauty salons, spas, or dermatology clinics, this pump is poised to become an essential tool for skincare aficionados.Aesthetics:Recognizing that presentation is as important as function, the Brass Lotion Pump features an elegantly crafted brass body. This distinctive design not only exudes a sense of luxury but also complements a wide range of skincare products, regardless of brand or packaging. The timeless appeal of brass enhances any vanity or bathroom decor, enhancing the overall aesthetics of the skincare routine.To ensure versatility and seamless integration, the pump is available in various finishes, from polished brass to antique bronze, catering to individual preferences and interior design requirements. By combining functionality with aesthetic appeal, [Company Name] has successfully created a product that harmonizes with the user's lifestyle while enhancing their skincare regimen.Sustainability:Driven by a commitment to environmental consciousness, [Company Name] has introduced eco-friendly elements to the Brass Lotion Pump. By incorporating recyclable materials and minimizing plastic usage, the company takes a significant step towards reducing its carbon footprint. The pump also features a refillable cartridge system, allowing users to periodically replenish their skincare products without the need for single-use plastic containers. This innovative approach promotes sustainability and aligns seamlessly with the current global drive towards a more eco-conscious society.[Company Name]'s initiative to prioritize sustainability does not end with the Brass Lotion Pump alone. The company actively collaborates with eco-friendly skincare brands, emphasizing the importance of responsible sourcing and manufacturing practices. Partnerships with organizations championing sustainable causes further contribute to [Company Name]'s overall mission to create products that are mindful of their ecological impact.Conclusion:The introduction of the Brass Lotion Pump marks a significant milestone in the skincare industry. With its unmatched functionality, appealing design, and unwavering commitment to sustainability, this innovative creation by [Company Name] promises to revolutionize the skincare experience for users worldwide. The pump's ergonomic efficiency, visually striking aesthetics, and environmentally conscious approach make it a must-have accessory for skincare enthusiasts looking to elevate their routines. As [Company Name] continues to push the boundaries of innovation, the Brass Lotion Pump positions itself as a game-changing product at the forefront of the evolving skincare landscape.

Gel Mixing Machine Manufacturer in Mumbai, India for Export and Supply

Amson Engineering, a well-known name in the manufacturing industry in India, specializes in producing a wide range of high-quality machinery and equipment. Their products find application across various industries, including pharmaceuticals, chemicals, cosmetics, and food processing. With an emphasis on innovation and quality, Amson Engineering is known for its ability to deliver superior products that meet their clients' specific needs.One such innovative product offered by Amson Engineering is the Gel Mixing Machine, which has been designed to meet the growing demand for high-quality gels across various sectors. The Gel Mixing Machine is an essential component in the manufacturing of gels and is widely used in industries such as pharmaceuticals, cosmetics, and food processing. The machine is used for creating a homogeneous gel, which is an essential aspect of the manufacturing process.The Gel Mixing Machine is manufactured using the latest technology and high-quality components, which enhances its durability and functionality. The machine is equipped with a powerful motor, which enables the users to mix gels quickly and efficiently. The Gel Mixing Machine is also designed to offer ease of use, thanks to its intuitive controls and ergonomic design.One of the key features of the Gel Mixing Machine is its versatility. It can be customized to meet the specific requirements of different industries and applications. The machine is available in various sizes and configurations, depending on the needs of the user. This makes it an ideal choice for small to large businesses, which require a reliable and efficient gel mixing solution.At Amson Engineering, quality is of utmost importance, and they follow stringent quality control measures to ensure that their products meet the highest standards. From sourcing high-quality components to manufacturing and testing, every aspect of the production process is carefully monitored to ensure the durability and functionality of the Gel Mixing Machine.In addition to their commitment to quality, Amson Engineering also focuses on providing exceptional customer service. They work closely with their clients to understand their requirements and offer customized solutions that meet their specific needs. Their team of experienced professionals is available to offer technical support and assist with any queries or concerns that clients may have.In conclusion, the Gel Mixing Machine from Amson Engineering is a versatile and reliable solution for the efficient mixing of gels in various industries. With a focus on innovation, quality, and customer service, Amson Engineering has established themselves as a leading manufacturer of high-quality machinery and equipment. Their commitment to excellence and customer satisfaction has earned them a reputation as a trusted partner for businesses across India and beyond.

Professional Brewery Plant Equipment for Perfect Beer Brewing: Customizable Options Available

DEGONG: A Leading Designer and Manufacturer of Beer Brewing EquipmentDEGONG, a Chinese-based company, is a highly specialized manufacturer of beer brewing equipment. The company is renowned for its innovative and high-quality brewing systems that suit the needs of both commercial and home brewers. The company offers a wide range of brewing equipment, including 5HL, 10HL, and 20HL professional brewery plant equipment that caters to the varying needs of its customers.DEGONG's team of engineers and technicians work hand-in-hand to design and manufacture complete beer brewery plant systems from start to finish. The company's unique business model, which emphasizes customization, allows customers to tailor-make their brewing systems to meet their specific requirements. DEGONG understands that every customer is unique, and that's why they offer a comprehensive consultation service to determine the most suitable brewing system for their business.DEGONG's comprehensive approach allows them to offer multiple brewing systems that can be customized and installed to fit each customer's brewing plan. Moreover, the company provides extensive guidance to customers who are new to the brewing industry, helping them choose the best equipment to suit their needs. This guidance includes advice on the size of the brewery equipment, the target market, and the brewing capacity. Furthermore, DEGONG offers training and support programs to help customers with the installation and operation of their newly purchased brewing equipment.DEGONG's 5HL, 10HL, and 20HL professional brewery plant systems possess a host of features that make them unique in the brewing industry. These features include:Precision in Temperature and Time ControlDEGONG's brewing equipment is equipped with top-of-the-line control systems to guarantee the precision control of time and temperature, ensuring customers achieve the desired beer characteristics.Energy-savingDEGONG's brewing equipment is designed and built to be energy efficient, this ensuring lower power consumption. The reduced energy consumption can translate into impressive savings on energy bills.Durable/ReliableDEGONG brewing equipment is made from high quality, durable materials that prevent rusting and corrosion, thus ensuring longevity and reliability.Ease of MaintenanceDEGONG's brewing equipment is designed with easy maintenance in mind. The company's systems are easy to clean, meaning less time spent on maintenance and more time spent on brewing beer.DEGONG has established itself as a leading manufacturer of beer brewing equipment for a variety of customers. The company has a proven track record of designing and building high-quality brewery equipment that exceeds customer expectations. DEGONG's dedication to customization, innovation, reliability, and after-sale service sets it apart from other brewing equipment manufacturers. From consultation through to installation and training, DEGONG's services are world-class.In conclusion, DEGONG is an expert in designing and manufacturing professional brewery plant equipment for brewing beer. The company offers customized brewing equipment that guarantees precision temperature and time control, reliability, energy efficiency, and ease of maintenance. Are you interested in starting or expanding a beer brewery business? DEGONG is the company that can help you achieve your goals. Contact DEGONG today and see how they can help you achieve your business objectives.

DIY Alcohol Dispensing Pump Bottle: Guide, Tools, Parts and Kits for Making Your Own Technology

The Importance of Plate Heat Exchangers in Efficient Heat Transfer

[Company Name], a leading provider of heat transfer solutions, is revolutionizing the industry with their state-of-the-art Plate Heat Exchangers. With their innovative technology and commitment to excellence, the company is poised to transform the way heat is transferred in various industries.Plate Heat Exchangers, also known as PHEs, are highly efficient devices that enable the transfer of heat between two fluids. They consist of a series of metal plates with intricate patterns, allowing for optimal heat transfer. The unique design of these heat exchangers ensures maximum efficiency and minimal energy consumption, making them ideal for various applications.One of the key advantages of Plate Heat Exchangers is their compact size. Compared to traditional heat exchangers, PHEs take up significantly less space, making them suitable for installations where space is limited. This compact size also facilitates easier maintenance and cleaning, reducing downtime and enhancing overall operational efficiency.Moreover, PHEs offer exceptional flexibility in terms of temperature control. The ability to precisely regulate the temperature of the two fluids being exchanged allows for better process control and improved product quality. This makes Plate Heat Exchangers ideal for industries such as food and beverage, pharmaceuticals, and chemical processing, where precise temperature control is crucial.Additionally, the modular design of Plate Heat Exchangers allows for easy expansion or modification of the system as per requirements. This scalability enables businesses to adapt to changing demands, ensuring they always have the right capacity to meet their production needs. The versatility of PHEs makes them a cost-effective solution for industries with fluctuating heat transfer requirements.[Company Name] has proven expertise in the design and manufacture of Plate Heat Exchangers. With a team of highly skilled engineers and technicians, the company continuously strives to innovate and improve its products. Their commitment to research and development ensures that customers benefit from cutting-edge heat transfer solutions that meet the highest quality standards.The company also offers comprehensive after-sales services, including installation, maintenance, and repairs. They understand the critical role that Plate Heat Exchangers play in the smooth operation of various industries, and thus provide prompt and reliable support to their customers. This commitment to customer satisfaction has earned them a solid reputation in the market.[Company Name] has a global presence and serves clients from diverse industries across the world. Their Plate Heat Exchangers have been successfully integrated into numerous applications, ranging from water heating and cooling systems to industrial process heat recovery. The company's client portfolio includes well-known names from industries such as food processing, HVAC systems, power generation, and more.By leveraging the power of Plate Heat Exchangers, [Company Name] is leading the way in efficient heat transfer solutions. Their commitment to innovation, quality, and customer satisfaction has positioned them as a trusted partner for industries seeking reliable heat transfer solutions. With their cutting-edge technology and unparalleled expertise, [Company Name] is set to redefine the industry standards and enhance the efficiency of heat transfer processes.